High-performance preforms for carbon pole caps for hydrogen tanks

✓ Are you a manufacturer of hydrogen tanks or carbon pole caps for hydrogen tanks?

✓ Do you need lightweight, pressure-resistant, corrosion-resistant and safe preforms for further processing in your pole caps?

✓ Are you looking for a supplier or manufacturer who can produce preforms for your pole caps cost-effectively using the TFP process?

TFP Technology manufactures high-performance carbon preforms for you as semi-finished products for further processing. We work with you to further develop your polar cap production.

Safe and extremely pressure-resistant

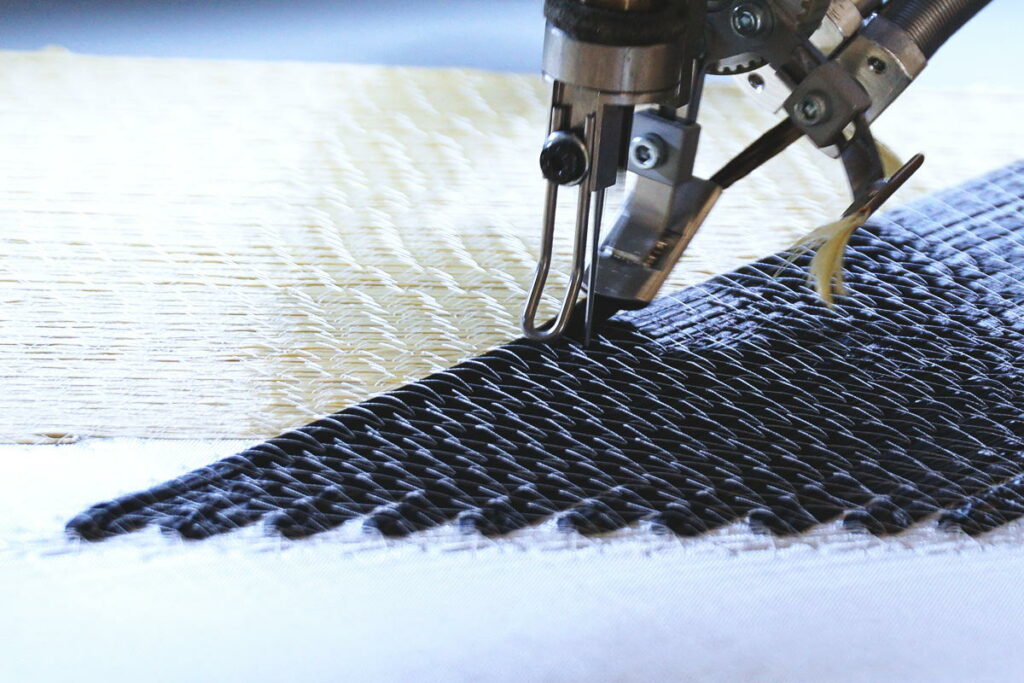

Safe and extremely pressure-resistant pole caps for hydrogen tanks are crucial for the storage and handling of hydrogen (H2), especially in vehicles and industrial applications. We use our innovative embroidery technology to produce high-performance carbon preforms for pole caps.

The TFP process (Tailored Fiber Placement) carbon fiber pole caps offer several advantages, especially in connection with hydrogen tanks, which have to meet high requirements in terms of safety, compressive strength and weight.

Advantages of carbon pole caps

- Weight reduction: Carbon is significantly lighter than conventional metal alloys. Lighter tanks improve the efficiency of hydrogen vehicles, as less energy is required to transport the tank itself.

- High pressure resistance: Carbon pole caps are extremely pressure-resistant and can withstand the high pressure requirements needed to store hydrogen (typically up to 700 bar). Despite their low weight, carbon materials offer high rigidity, which supports the structural integrity of the tank.

- Corrosion resistance: Carbon is corrosion resistant and does not react with hydrogen or other chemicals, which extends the service life of the tanks. As carbon does not corrode, less maintenance is required, which reduces operating costs.

- Safety advantage: In contrast to certain metals, which are susceptible to hydrogen embrittlement, carbon is insensitive to this phenomenon. This increases the safety and reliability of the tanks.

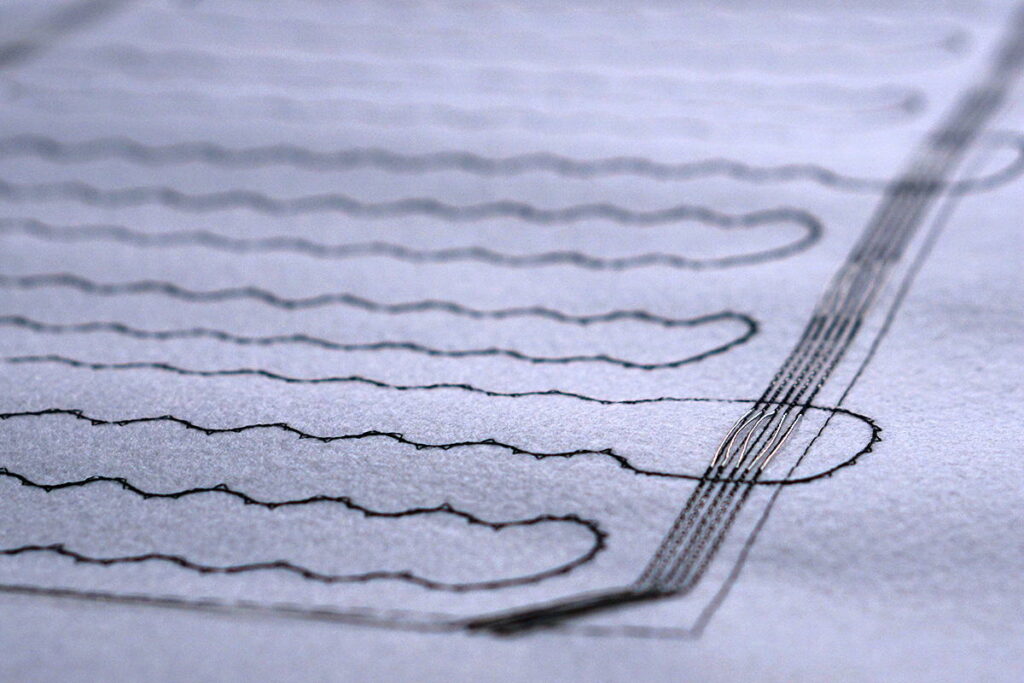

- Customizable shaping: Carbon preforms can be individually manufactured using our embroidery technology and shaped into complex forms that meet specific design requirements. During the preforming process, the fibers are laid down according to load.

- Combination with other fibers: The TFP process allows several fibers to be combined, including carbon fibers with Kevlar and glass fibers. This results in improved energy absorption in the pole cap area on impact with a solid surface.

Functions and requirements

Safety aspects

Polar caps are crucial for the safety of hydrogen tanks. They must be extremely tight and resistant to prevent hydrogen from escaping, as hydrogen is a very light and highly flammable gas.

Pressure resistance

Hydrogen is often stored at high pressures (up to 700 bar). Pole caps must therefore be extremely pressure-resistant to ensure the integrity of the tank.

Choice of material

The materials used to make polar caps must be corrosion-resistant and compatible with hydrogen. Special alloys and plastics are often used that work reliably under these extreme conditions. Carbon fibers offer decisive advantages here.

Challenges

Hydrogen embrittlement

A major problem when using metal alloys is hydrogen embrittlement, where hydrogen penetrates the metal and makes it brittle. Materials must therefore be selected that are resistant to this effect.

Leakage control

Even the smallest leaks can be dangerous. The development and testing of pole caps therefore includes rigorous test procedures to ensure tightness.

Temperature management

Since hydrogen tanks are often exposed to extreme temperatures, polar caps must also take thermal expansion into account.

Applications of hydrogen (H2)

Vehicles

In fuel cell vehicles, pole caps are a critical component of the hydrogen storage tanks, which are necessary for the safe operation of the vehicle.

Industrial applications

In industry, where hydrogen is handled in large quantities, polar caps play a central role in the safe storage and distribution of the gas.

Carbon preforms for pole caps from the manufacturer TFP Technology

We manufacture high-performance carbon fiber preforms for you as semi-finished products for further processing in your hydrogen tanks. The TFP process is used to produce lightweight and highly pressure-resistant carbon preforms in the most complex shapes. A combination of different fibres allows you to optimize further safety-relevant properties of your hydrogen tanks.

Carbon impresses with its corrosion resistance and insensitivity to hydrogen embrittlement.

We look forward to hearing from you and will be happy to help you optimize your hydrogen tanks.

Read on and find out more about:

Further contributions

Electric heat mats for seat heating in commercial vehicles

✓ Are you a manufacturer of commercial vehicles or a supplier for seats in the commercial vehicle industry?

✓ Do you need robust and reliable seat heaters that can be flexibly adapted to your seat configurations – in small or medium quantities from 500 to 2000 units?

✓ Are you looking for a ready-to-plug-in, cost-effective solution with minimal installation effort?

Then read on!

Cost-effective heat mats for mattress heating in series production

✓ Are you a manufacturer of heated underblankets and other heating solutions for mattresses?

✓ Do you need reliable and robust heat output with minimal energy consumption?

✓ Are you looking for a cost-effective alternative for your mattress heat mats?

Then read on!

Electric heat mats for fans in heat pumps as an alternative to silicone heat mats

✓ Are you a manufacturer of fan components or fans for heat pumps?

✓ Are you faced with the challenge of keeping your fans or ventilators ice-free (anti-icing)?

✓ Are you looking for a cost-effective alternative to the silicone heat mat you have been using up to now?

Then read on!