Cost-efficient heat mats for manufacturers of IBC heaters

✓ Do you manufacture heaters for IBC containers?

✓ Are you looking for efficient and reliable heat mats for further processing in your IBC heating system?

✓ Are you looking for effective, robust and inexpensive heat mats for your IBC heating system?

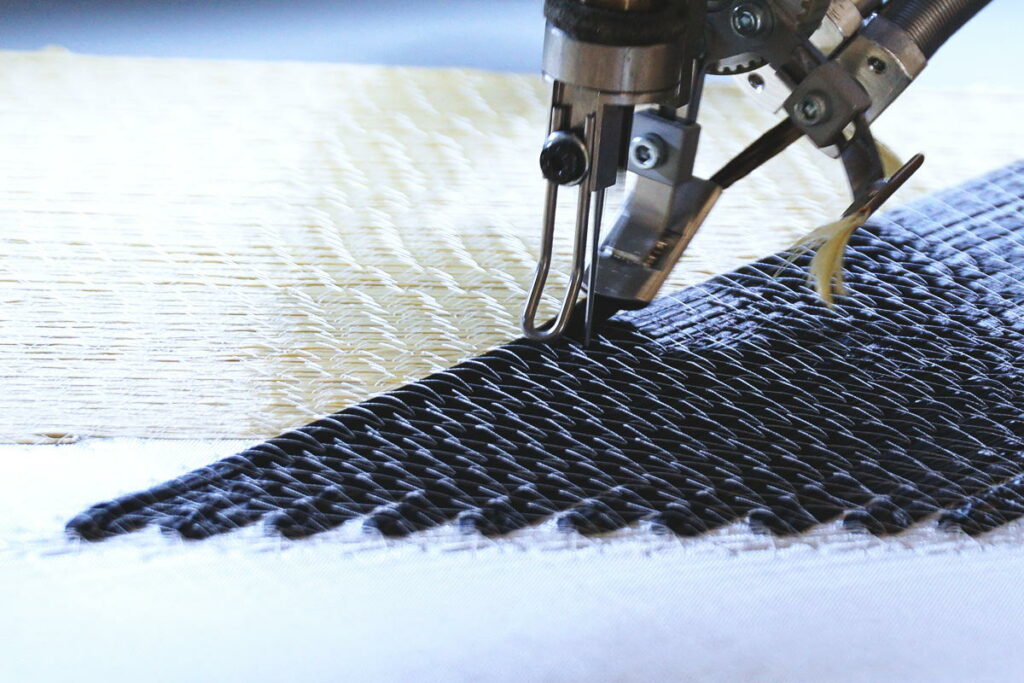

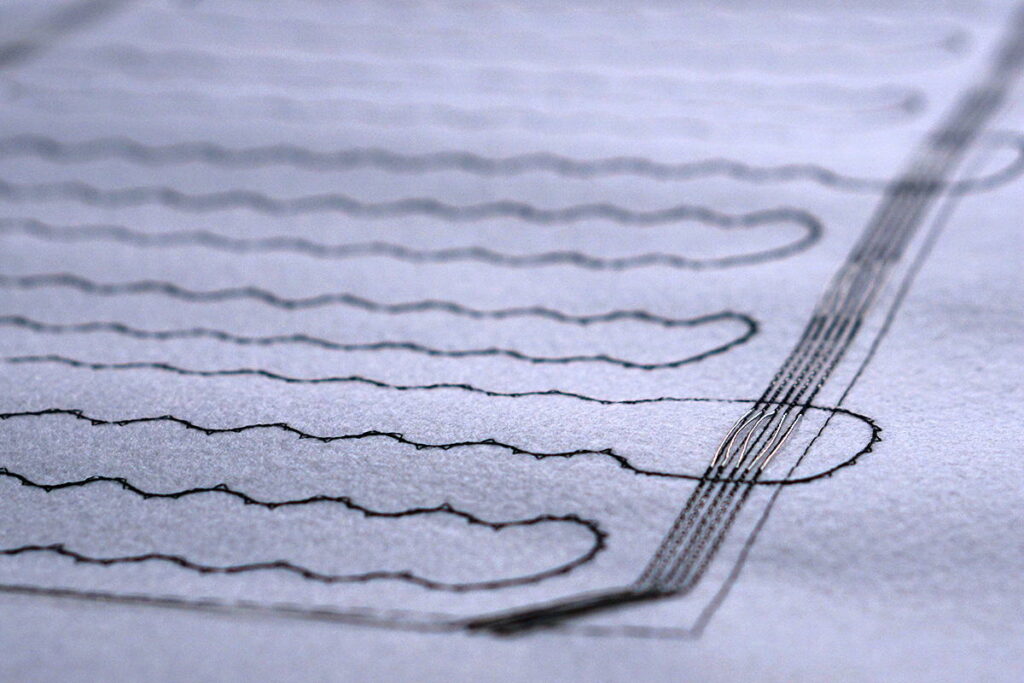

We produce heat mats or heating jackets for manufacturers of IBC heaters (B2B) using cost-effective embroidery technology. Made in Germany.

We work with you to develop the right heat mats in terms of size, shape, output and heating conductor layout for your IBC heating system.

IBC heating with individual temperature control

A heater for IBC containers ensures that the stored liquids or goods are kept at a constant temperature. For example, they protect substitute precipitants in sewage treatment plants against frost and crystallization, prevent flocculation of various substances or ensure the desired viscosity for production processes.

IBC heat mats from TFP impress with their precise and individually adjustable temperature control. A permanently constant temperature maintains the quality of the products. At the same time, it maximizes energy efficiency and saves heating costs. Offer your customers an IBC heater with one or more heating zones that individually heat different areas of the container to meet the specific requirements of the stored materials.

Conventional heating solutions transfer the heat directly to the contents. Flexible heat mats or heating jackets heat the air between the heating jacket and the container wall. The heated air transfers the heat to the container wall and leads to uniform heating of the contents without direct contact.

We manufacture cost-effective flexible heat mats that you can use as heating jackets or heating sleeves in your IBC heating system. We work with you to develop the right heat mats in terms of size, shape, output and heating conductor layout for your IBC heating system.

Robust heat mats for IBC containers for industrial applications

Our heat mats for IBC containers are extremely durable and robustly constructed to withstand the harsh conditions of industrial environments. The design ensures a long service life and reliability, even under demanding conditions such as strong vibrations or extreme temperatures. The coat can also be easily cleaned with water or soapy water if it gets dirty.

The heating jacket can be attached to the container quickly and easily. This minimizes installation time and increases flexibility of use. Compared to conventional methods such as heating baths or heating chambers, heating jacket solutions are more cost-effective and allow the containers to be installed quickly and easily at any location.

Increased safety thanks to protection class 2

The safety of our products is our top priority. Double-insulated heating elements significantly minimize the risk of short circuits and increase safety for employees and materials.

All in all, our industrial heating jackets and container heaters stand for maximum reliability, flexibility and safety. They are the ideal choice for manufacturers of IBC heaters who are looking for reliable heating systems that offer optimum protection and maximum efficiency.

What are IBC containers?

IBC stands for Intermediate Bulk Containers, abbreviated to IBC. IBC containers are standardized containers for the storage and transport of liquids. They consist of a plastic tank with a lid and outlet device, which is protected by a metal frame. They are used in many sectors, for example in the chemical, food and beverage, pharmaceutical, agricultural and cosmetics industries.

What are the advantages of IBC containers?

IBC tanks offer many advantages for the storage and transportation of liquids:

- As standardized packaging, they reduce storage and transport costs.

- They simplify handling and logistics.

- They maximize storage efficiency.

When do ICB containers need to be heated?

IBC heaters are used when the stored liquids have certain ambient temperature requirements or must not freeze.

Offer your customers heaters for IBC containers for these applications:

- In winter: An IBC heater prevents the stored liquids from freezing and reduces damage to containers and outlet fittings. It guarantees perfect product quality.

- For temperature-sensitive products: A container heater provides precise temperature control and keeps the stored liquids or chemicals at a constant temperature. It maintains the desired product properties and supports processing and production processes.

- For long-term storage: no condensation forms in the heated IBC tank, which guarantees the quality of the stored goods over longer periods of time.

- During transportation: The container heater guarantees constant temperatures during transportation regardless of the prevailing climate and weather conditions.

- In industrial processes: A heating mat for IBC containers provides precise temperature control and thus establishes and ensures important process parameters (e.g. consistency of the liquid) for processing.

What heating solutions are available for IBC tanks?

There is a suitable heating solution for every type of stored goods, ambient conditions and other factors with one of the following options:

- Flexible IBC heating mats (also heating jackets, heating blankets) for use on the outside of IBC containers. A heating mat of the appropriate size and heating capacity is wrapped around the container and ensures even temperatures.

- IBC heating jackets are flexible heating mats that are only attached to the lower part of the container and protect against freezing.

- IBC heating plates are flat heating elements that are mounted on the underside of the IBC tank and heat the liquid from the bottom upwards.

- Flexible IBC heating hoses heat the liquid inside the container directly.

- IBC heating pads lie on the top of the container and heat the liquid from top to bottom.

TFP is your manufacturer for flexible heating mats and heating jackets that you can process in your IBC heating system. Get in touch now!

What criteria are decisive for selecting the right heating solution for IBC containers?

A safe and effective container heating system takes these factors into account when selecting the right heating solution:

- Type of liquid stored

- Ambient temperature and climatic conditions

- Required temperature range and control

- Safety requirements

- Simple installation and operation

- Energy efficiency of the heating solution

Read on and find out more about:

- Electric heating elements made of insulated metals or carbon fibers for precisely controllable and efficient heat dissipation

- Textile sensors for measuring various data for seamless integration into electric heat mats

Further contributions

Electric heat mats for seat heating in commercial vehicles

✓ Are you a manufacturer of commercial vehicles or a supplier for seats in the commercial vehicle industry?

✓ Do you need robust and reliable seat heaters that can be flexibly adapted to your seat configurations – in small or medium quantities from 500 to 2000 units?

✓ Are you looking for a ready-to-plug-in, cost-effective solution with minimal installation effort?

Then read on!

Cost-effective heat mats for mattress heating in series production

✓ Are you a manufacturer of heated underblankets and other heating solutions for mattresses?

✓ Do you need reliable and robust heat output with minimal energy consumption?

✓ Are you looking for a cost-effective alternative for your mattress heat mats?

Then read on!

Electric heat mats for fans in heat pumps as an alternative to silicone heat mats

✓ Are you a manufacturer of fan components or fans for heat pumps?

✓ Are you faced with the challenge of keeping your fans or ventilators ice-free (anti-icing)?

✓ Are you looking for a cost-effective alternative to the silicone heat mat you have been using up to now?

Then read on!