Electric heat mats for fans in heat pumps as an alternative to silicone heat mats

✓ Are you a manufacturer of fan components or fans for heat pumps?

✓ Are you faced with the challenge of keeping your fans or ventilators ice-free (anti-icing)?

✓ Are you looking for a cost-effective alternative to the silicone heat mat you have been using up to now?

TFP Technology has the solution for keeping fan components ice-free even in extremely cold conditions: We produce heating elements for fans in heat pumps cost-effectively as semi-finished products in the form of heat mats for you as a manufacturer of fan components (B2B).

Anti-icing and de-icing in heat pumps with heat mats

Fan components are crucial for the functionality of various devices that are operated in extreme weather conditions.

In areas where ambient temperatures regularly fall below freezing, there is a risk of moisture condensing and freezing on the surfaces of fans and other components.

This impairs heat exchange and reduces the efficiency of the system.

In extreme cases, heavy ice formation can cause the heat pump to stop working properly.

Heat pumps are energy-efficient appliances that are used for both heating and cooling buildings.

They work by extracting heat from a source (air, water or earth) and bringing it to a higher temperature level.

In cold climates, ice forms on the external components, particularly the evaporator and fan.

Our electric heat mats for fan components provide a remedy here.

They also offer you a cost-effective and efficient alternative to conventional silicone heat mats:

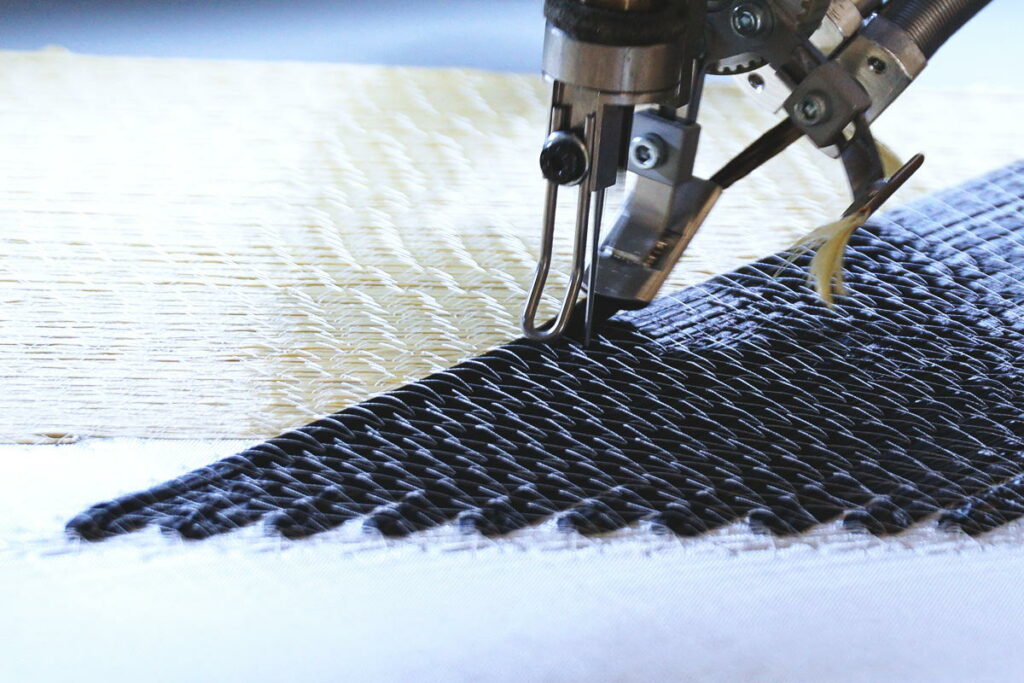

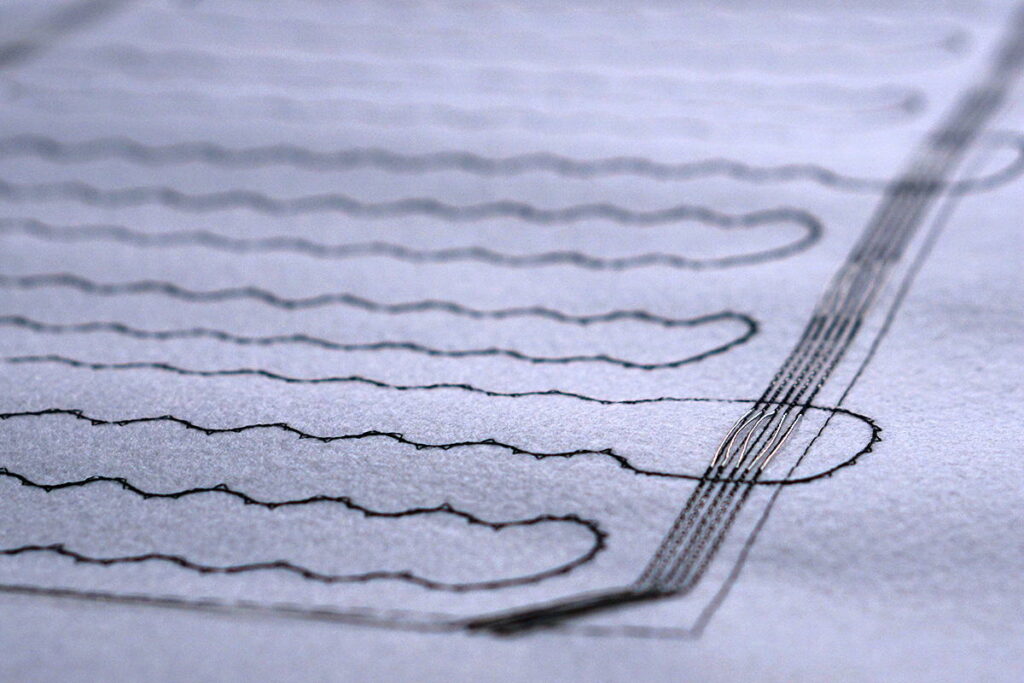

- For the electrical heating elements for anti-icing and de-icing, we embroider fine wires as heating conductors onto various carrier materials.

- You integrate the heating elements into the surfaces to be protected, such as your fan components or fans for heat pumps.

- As soon as an electrical voltage is applied to these wires, they generate heat that effectively prevents the formation of ice (anti-icing) or melts ice that has already formed (de-icing).

Anti-icing and de-icing technologies for fans / ventilators

There are various anti-icing technologies that prevent condensation and subsequent icing.

Our technology, the heat mat from TFP, is cost-effective, environmentally friendly, energy-saving, effective and can be manufactured individually in series production.

The following technologies are generally used:

1 Defrosting function (defrosting)

Many heat pumps are equipped with automatic defrost cycles.

These cycles are activated when a certain amount of ice is detected on the evaporator.

The heat pump then temporarily switches to cooling mode to conduct the heat from the inside to the outside and melt the ice.

Advantages: Automatic operation, complete iron removal

Disadvantages: High energy consumption, temperature fluctuations and faster wear and tear.

2 integrated heating elements or heat mats

Heating elements integrated into fans and other components keep the surface temperature above freezing point.

These elements are only activated when required in order to save energy.

TFP Technology manufactures such heat mats.

Advantages: Targeted ice prevention, energy-saving, prevention of frost damage, longer service life, environmentally friendly, cost-effective

Disadvantages: Slight increase in total cost of ownership

3 integrated silicone heat mats

Silicone heat mats are flexible heating elements that have been used for years in anti-icing technology.

They offer even heat distribution and are resistant to extreme temperatures.

They are reliable and easy to integrate into heat pump fan components.

However, the operating costs can be higher, which is why more efficient alternatives such as the textile heat mats from the manufacturer TFP Technology are increasingly preferred.

Advantages: Even heat distribution, high flexibility, easy integration into existing systems.

Disadvantages: Higher operating costs, limited energy efficiency, potentially shorter service life compared to newer alternatives.

4 Coatings

An anti-icing coating with hydrophobic (water-repellent) properties is applied to the fan components to prevent the adhesion of ice.

These coatings are often able to delay or even completely prevent ice formation.

Advantages: Requires no energy

Disadvantages: Chemical treatment, not sustainable, limited effectiveness

5 Optimized design and control systems

Modern heat pumps are often designed to minimize ice formation through optimized airflow and improved control algorithms.

These systems continuously monitor the operating conditions and adjust the operation of the heat pump accordingly.

Advantages: Longer service life, increased efficiency, less maintenance

Disadvantages: Higher acquisition costs, complex, software dependency

Applications of anti-icing in other areas

Anti-icing and de-icing technologies are used in many areas, not just for fan components.

The most important areas of application include

- Transport & traffic: In aviation, these technologies prevent the formation of ice on aircraft wings and in engines.

They are also used in road traffic, rail vehicles and the maritime industry to increase safety. - Construction & architecture: They are used on roofs, gutters and external staircases of buildings to prevent ice from forming.

They are also very important in public infrastructure, for example on bridges, stairs, walkways and platforms. - Industry: Anti-icing and de-icing technologies are used in aviation, road transport, agriculture and the energy industry to maintain operations in cold weather conditions and minimize downtime.

We produce heating elements as semi-finished products for you

Get in touch with us and discuss your requirements for an electric heat mat for your fan components, e.g. shape, layout and carrier material, with our TFP experts.

Together with you, we develop a heating element as a semi-finished product for further processing in your fan components.

We embroider heating conductors onto a near-net-shape cut carrier material that heats your component in exactly the right places.

We produce a sample that you can use and test in your production. After your approval, we start production of the heat mats for your fan components in small or large series at our site in Falkenstein / Vogtland.

Read on and find out more about:

- Electric heating elements & heat mats

- Anti-icing and de-icing with heating elements

- Technology

Further contributions

Electric heat mats for seat heating in commercial vehicles

✓ Are you a manufacturer of commercial vehicles or a supplier for seats in the commercial vehicle industry?

✓ Do you need robust and reliable seat heaters that can be flexibly adapted to your seat configurations – in small or medium quantities from 500 to 2000 units?

✓ Are you looking for a ready-to-plug-in, cost-effective solution with minimal installation effort?

Then read on!

Cost-effective heat mats for mattress heating in series production

✓ Are you a manufacturer of heated underblankets and other heating solutions for mattresses?

✓ Do you need reliable and robust heat output with minimal energy consumption?

✓ Are you looking for a cost-effective alternative for your mattress heat mats?

Then read on!

Fiber preforms for carbon ship propellers

✓ Are you a manufacturer of ship propellers or boat propellers? ✓ Are you looking for lightweight, high-strength, corrosion-resistant carbon propellers with an optimized and complex design? ✓ Are you looking for a supplier or manufacturer of carbon fiber reinforced boat propellers which can develop complex geometries with you and produce them cost-effectively? Then read on!