Menu

Close

✓ With rigid + lightweight preforms made from fiber strands

✓ exactly where you need the structural performance

✓ with a fiber orientation that supports the force curves of your product or component.

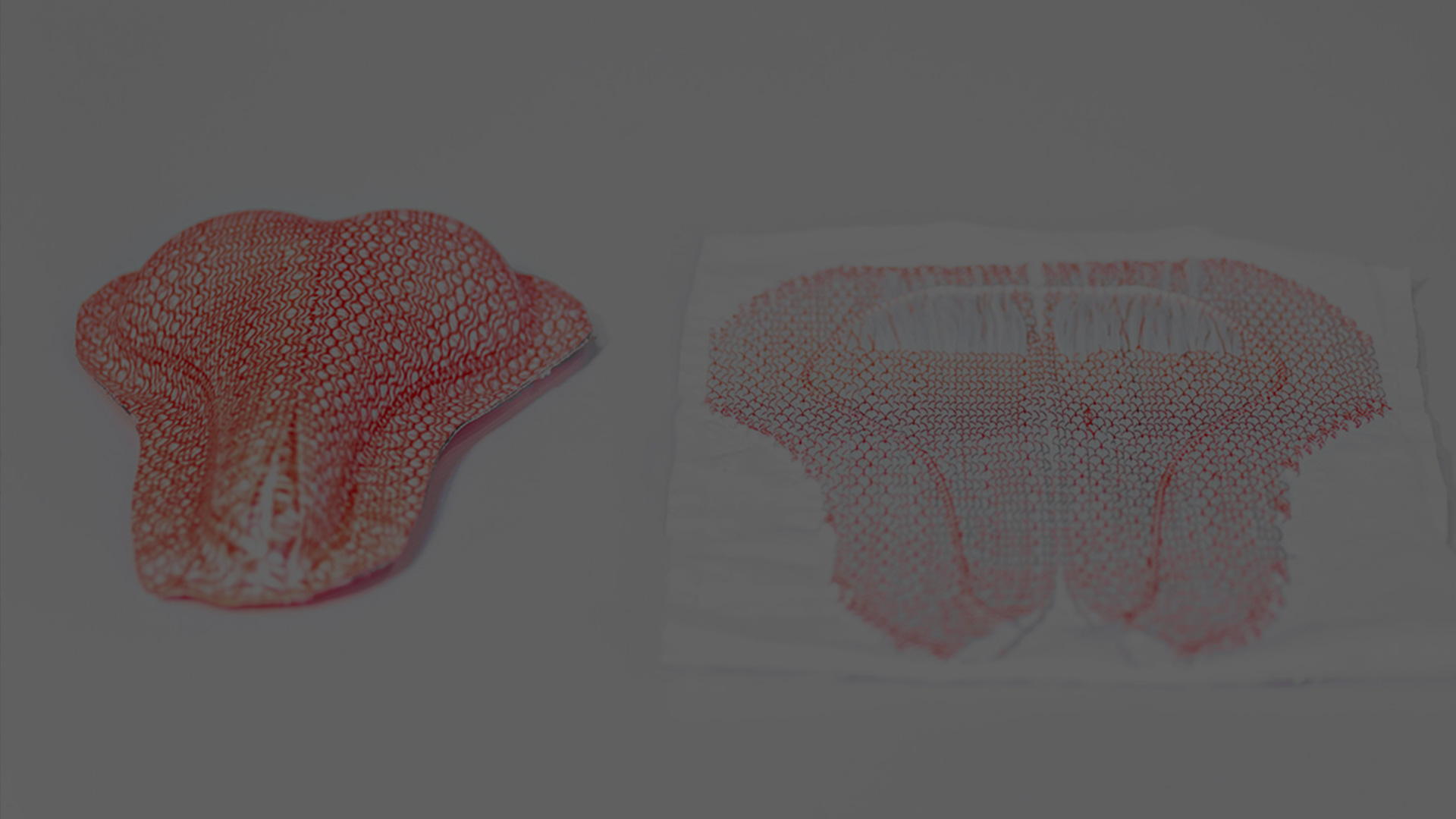

Reinforcement structures are at the heart of our fiber preforms. They absorb the loads, distribute them and thus determine the mechanical properties of the finished composite material. These structures significantly determine the strength, rigidity and durability of your end product.

We supply you with complex and high-performance reinforcement structures in high quality. Our process integrates design, precision manufacturing and quality assurance.

Using advanced CAD software, we work with you to plan the shape of the components and the specific arrangement of the reinforcing fibers – exactly where you need the structural performance.

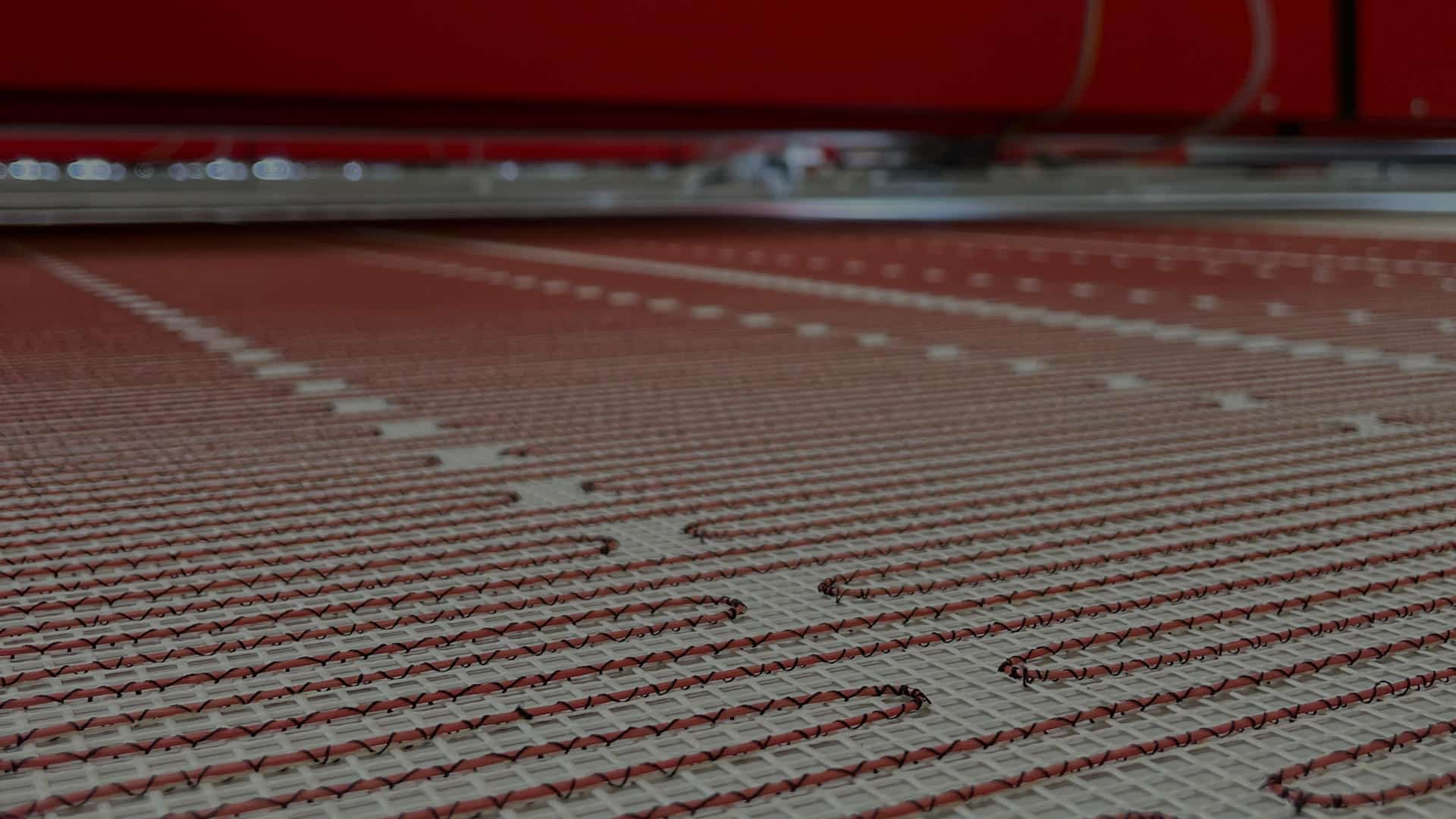

We use our CNC embroidery machines to produce the complex patterns and structures of the reinforcing fibers for you.

The near-net-shape production results in a maximum of 3 % fiber rejects or waste.

The reinforcement structures are created by precisely embroidering high-performance fibers such as carbon, glass fiber and aramid onto a carrier material or fabric. Whether classic nonwovens, special films or stretchable textiles, we apply the fibers to any desired flexible carrier material. Right from the start, we make sure that the carrier material is optimally suited to your requirements, your product and the planned application, and that production remains cost-efficient.

Do you need pure reinforcement structures without carrier material? There is also a solution for this: use removable fleeces or films that can be removed without leaving any residue using water, heat or tearing.

No matter what challenge you are currently facing with your product or component, let’s work together to find a way to achieve customized reinforcement.

Get in touch with us! We look forward to your idea or challenge!

Using an advanced TFP process, we produce fiber preforms especially for processing with thermoplastics.

Using an innovative TFP process, we produce fiber preforms for thermoset processing.

Integrate a heating function seamlessly and homogeneously into your fiber composite component or plastic product!

Seamlessly expand your fiber composite component with necessary or additional functions, such as damage sensing, measurement data acquisition, data transmission and much more!