Fiber preforms with carbon for UAVs and drones for industry

✓ Are you a manufacturer of innovative UAVs (unmanned aerial vehicles) for industry or the military?

✓ Do you want to make your drone lighter, more robust, more maneuverable or more durable?

✓ Are you looking for a supplier or manufacturer who will work with you to develop and cost-effectively manufacture a customized reinforcement for various parts of your UAV?

Then read on!

TFP Technology develops and manufactures fiber preforms with carbon for further processing using thermoset processes for you as a UAV manufacturer (B2B) – cost-efficiently and with a high level of reproducibility.

Together with you, we develop an individual fiber preform for the targeted reinforcement of various parts of your UAV.

Optimize your UAV with carbon structures

In the rapidly growing world of drone technology, innovation is at the forefront, especially in the defense industry, large-scale industry and other professional applications. Keyword: TFP and carbon.

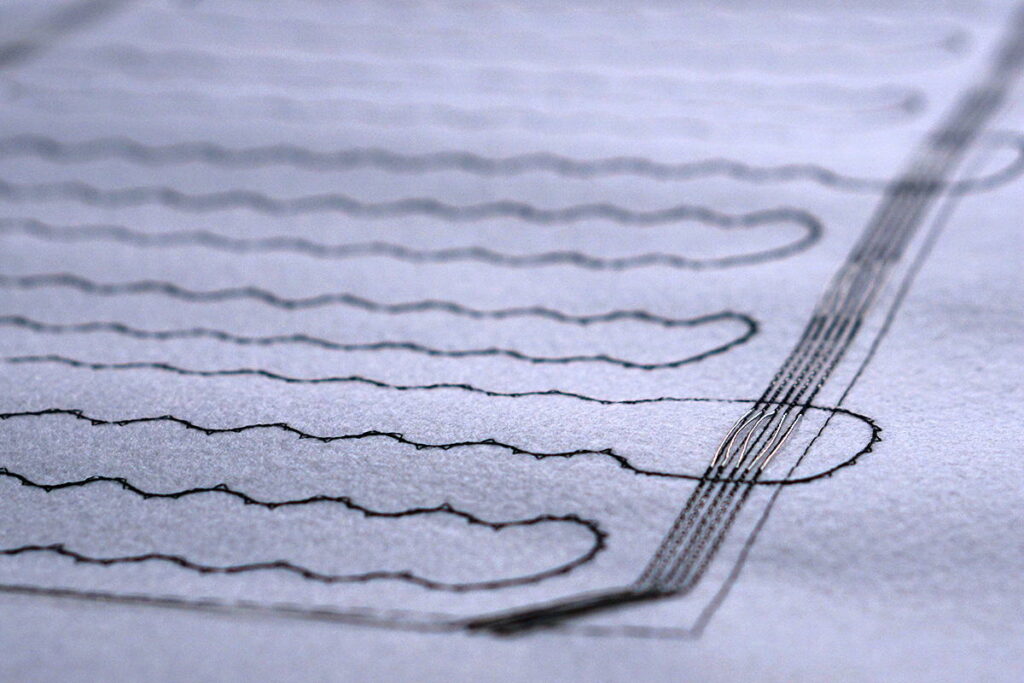

Tailored Fiber Placement (TFP) and carbon fibers can be combined to produce tailor-made parts as preforms that offer an excellent balance of weight and strength with maximum performance and efficiency.

From improving aerodynamic efficiency to increasing structural robustness, the TFP process combined with carbon offers a wealth of benefits that redefine the limits of what drones can do. Whether tricopter, quadcopter, hexacopter, octocopter and co.

Advantages of carbon for drones

- Weight saving: Carbon fiber reinforced plastics (CFRP) are known for their high strength and low weight. The targeted placement of fibers using TFP makes it possible to produce structures that are very light yet extremely resilient. This leads to improved performance and efficiency of the drone, as the overall weight is reduced.

- Increased strength and stiffness: The targeted arrangement of the fibers makes it possible to maximize the strength and stiffness of the structure exactly where it is needed. This results in an overall more robust and stable drone that is more resistant to loads and vibrations.

- Tailor-made properties: Carbon fibers in combination with TFP make it possible to adapt the mechanical properties of the structure precisely to the requirements of the design. This allows structures to be developed that optimize specific performance characteristics such as flexural strength, tensile strength or impact strength.

- Improved aerodynamic efficiency: By using carbon fibers in wings, fuselages and propellers, drones can be aerodynamically optimized, resulting in improved flight performance and efficiency. The smooth surface and tailored structure reduce drag and improve maneuverability.

- Longer service life and low maintenance: Carbon is corrosion-resistant and shows high resistance to fatigue and wear. As a result, drones that use CFRP structures often have a longer service life and require less maintenance compared to those with conventional materials.

Drones made of carbon: propellers, frames, housings and more

The TFP process can be used to produce numerous different parts for drones, which are particularly impressive due to their low weight and high strength. Among other things, we manufacture for you:

Fuselage, frame and wings:

Carbon fiber reinforced plastics (CFRP) are often used for the structure of drone fuselages, frames, chassis or even wings, as they offer high strength combined with low weight. By using TFP, the fibers can be placed in precisely defined areas to maximize strength where it is needed most, while avoiding unnecessary weight in other areas.

Rotors and propellers:

Carbon fibers are used in rotors and propellers or winglets of drones to make them lighter and at the same time more resistant to loads. TFP can help to optimize the structural integrity and efficiency of these components.

Landing gear, housings and more:

Carbon fibers are also suitable for the landing gear and housings of drones to make them more robust and resistant to impacts and other environmental influences. Battery base carriers, notching devices, motor carriers, three-blade holders, etc. are other possible areas of production.

Areas of application for UAVs and drones

The use of UAVs or drones is not limited to the private sector; unmanned flying objects are becoming increasingly important in industry and other sectors of the economy.

- Defense industry / military: As unmanned flying objects for various purposes.

- Air traffic: control of runways or aircraft maintenance.

- Logistics: transportation of goods and facilitation of storage work.

- Energy industry: Inspection of wind turbines or solar parks.

- Agriculture: Control of agricultural land for better management.

- Construction and real estate industry: Use for planning and surveying.

- Further areas of application: Large-scale industry, marketing, film industry, traffic management and many more

How does the TFP process for optimizing UAVs, military drones or industrial drones work?

Get in touch with us and discuss with our TFP experts which features of your UAV you would like to optimize.

Together with you, we develop a fibre preform as a semi-finished product for further processing in your UAV, which optimizes exactly the desired parameters:

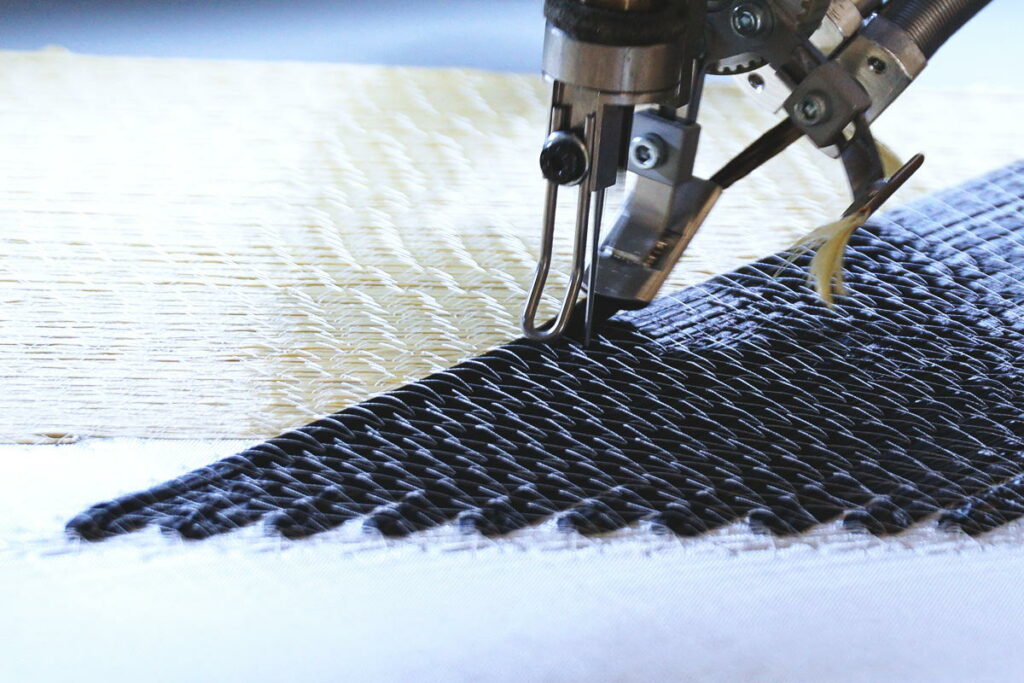

We embroider carbon fibers onto a near-net-shape cut carrier material that reinforces your component in exactly the right places.

We produce a sample that you can use and test in your production. After your approval, we start production of your carbon reinforcement in small or large series at our site in Falkenstein / Vogtland.

Read on and find out more about:

- Fiber preforms

- Reinforcement structures

- Further processing using thermosetting processes

- Technology

Further contributions

Electric heat mats for seat heating in commercial vehicles

✓ Are you a manufacturer of commercial vehicles or a supplier for seats in the commercial vehicle industry?

✓ Do you need robust and reliable seat heaters that can be flexibly adapted to your seat configurations – in small or medium quantities from 500 to 2000 units?

✓ Are you looking for a ready-to-plug-in, cost-effective solution with minimal installation effort?

Then read on!

Cost-effective heat mats for mattress heating in series production

✓ Are you a manufacturer of heated underblankets and other heating solutions for mattresses?

✓ Do you need reliable and robust heat output with minimal energy consumption?

✓ Are you looking for a cost-effective alternative for your mattress heat mats?

Then read on!

Electric heat mats for fans in heat pumps as an alternative to silicone heat mats

✓ Are you a manufacturer of fan components or fans for heat pumps?

✓ Are you faced with the challenge of keeping your fans or ventilators ice-free (anti-icing)?

✓ Are you looking for a cost-effective alternative to the silicone heat mat you have been using up to now?

Then read on!